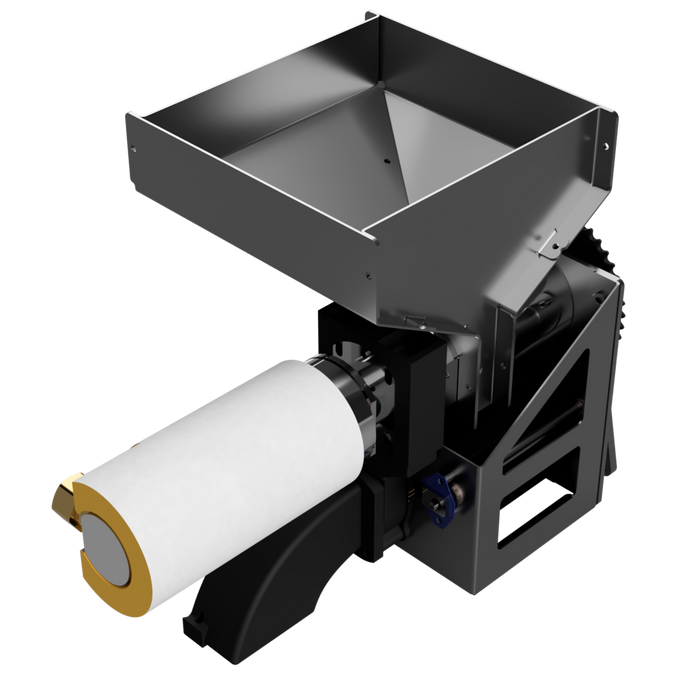

Inspired by 3D printing, MixFlow technology changes how plastic is melted. The result? A more efficient, higher quality, and more affordable way to extrude plastic.

Proven Performance

Improved Performance

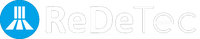

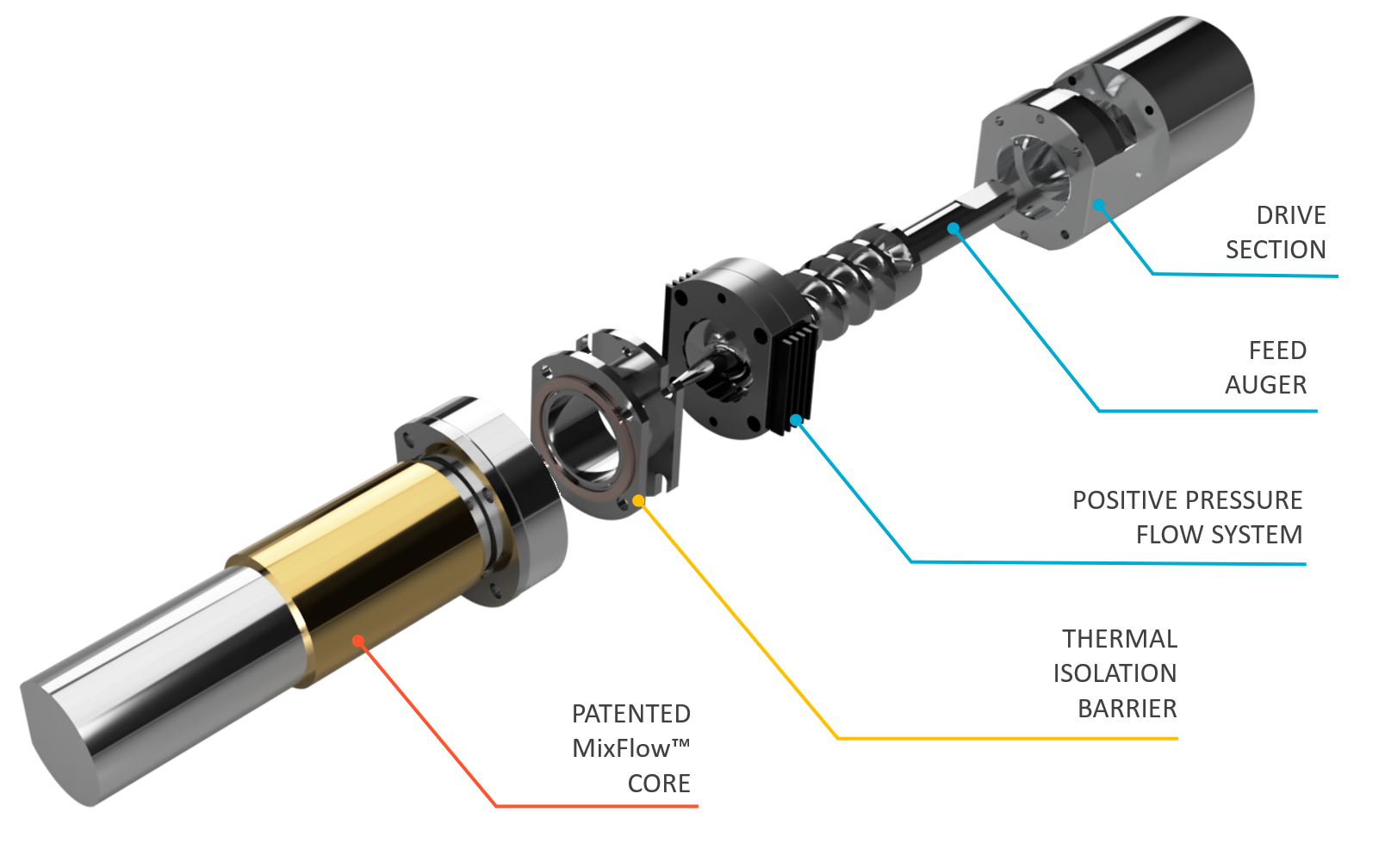

Traditional systems churn a screw through molten plastic to ensure it's properly melted. This requires extra energy, and causes more wear and tear on components. MixFlow separates the drive section and melt section with a thermal isolator - just like in 3D printing - reducing energy consumption up to 75%, while improving throughput.

Contact our sales team today to learn how MixFlow can improve your 3D printing experience.

Reduced Cost

Because MixFlow doesn't need to churn a long screw through the molten plastic - which takes significant energy - it's more affordable to produce, and lasts longer than competing technologies. This allows ProtoCycler V3 to offer both the highest performance and best value on the market.

Higher Quality

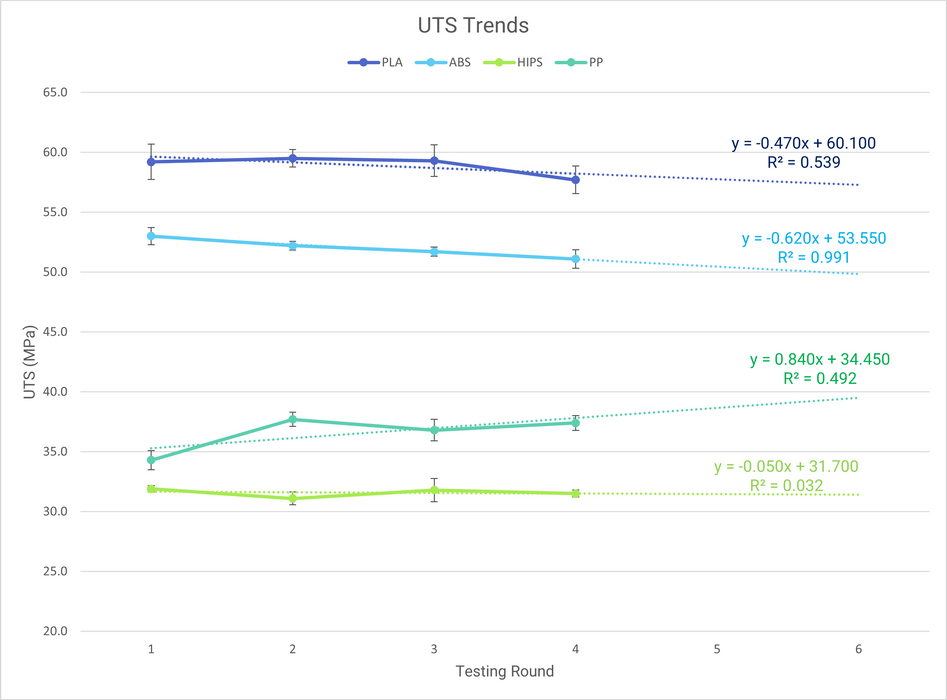

Traditional systems degrade plastic every time it's extruded, weakening it by 10% or more. MixFlow uses lower energy processes that preserve plastic quality, reducing degredation to 1% or less. This results in higher quality, stronger filament - even when it's recycled.

Contact our sales team today to access the full study.