ProtoCycler V3 combines cutting edge technology and intelligent software to accelerate your productivity. That's why it's the extruder of choice for leading businesses around the world.

Trusted by the Best

Expand Your Business

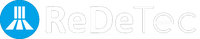

In addition to one of the largest material selections on the market, ProtoCycler V3 can be used to create custom filament, including otherwise unavailable blends. Our proven technology facilitates all common 3D printing filaments in any color you desire for prototyping, including PLA, ABS, HIPS, PETG, PA12, and many more.

Develop New Solutions

Create all new blends of filament to give your business a competitive edge. Our powerful AI driven software allows you to monitor your experimentation in real time, making necessary tweaks and monitoring changes as you go. Then, review and study your data to guide the next round of experimentation prototyping.

Increase Your Productivity

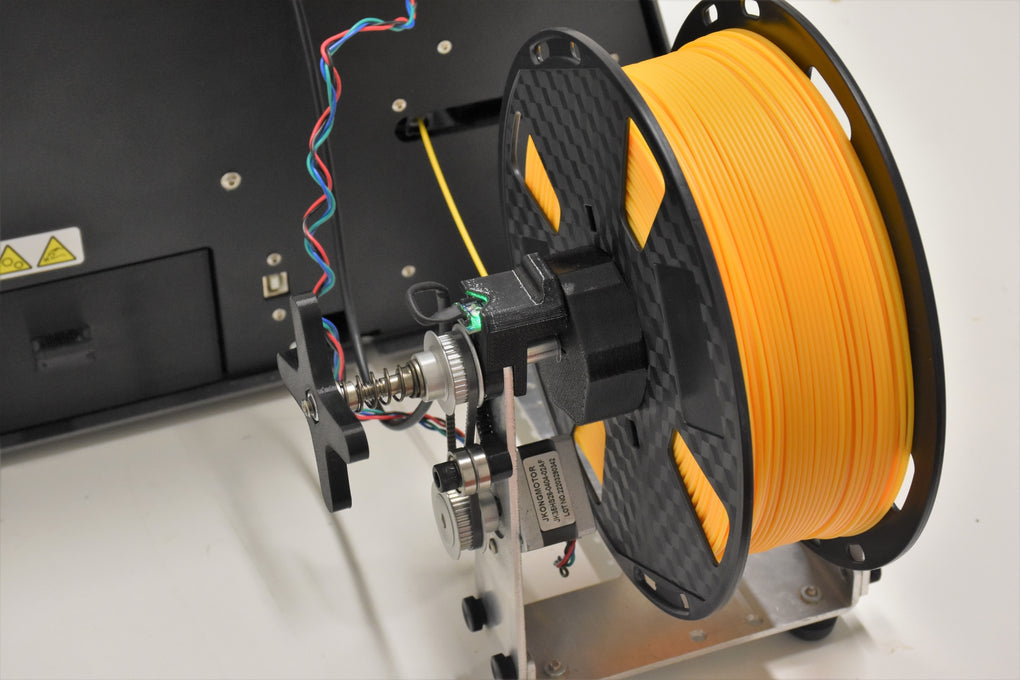

Time is money. That's why ProtoCycler is the only system on the market to use advanced control algorithms to handle every aspect of filament creation - from extrusion, to cooling, to spooling - completely automatically. Effortlessly create spool after spool of 3D printing filament with ProtoCycler V3.

Automate Your Production

ProtoCycler V3 allows you to create proprietary, automated profiles with full control over every aspect of filament extrusion. Deploy your new polymer blends across your business with speed, accuracy, and precision.

Chat with a member of our sales team to see how ProtoCycler V3 can bring your business to the next level.

A Prototyping & Production Powerhouse

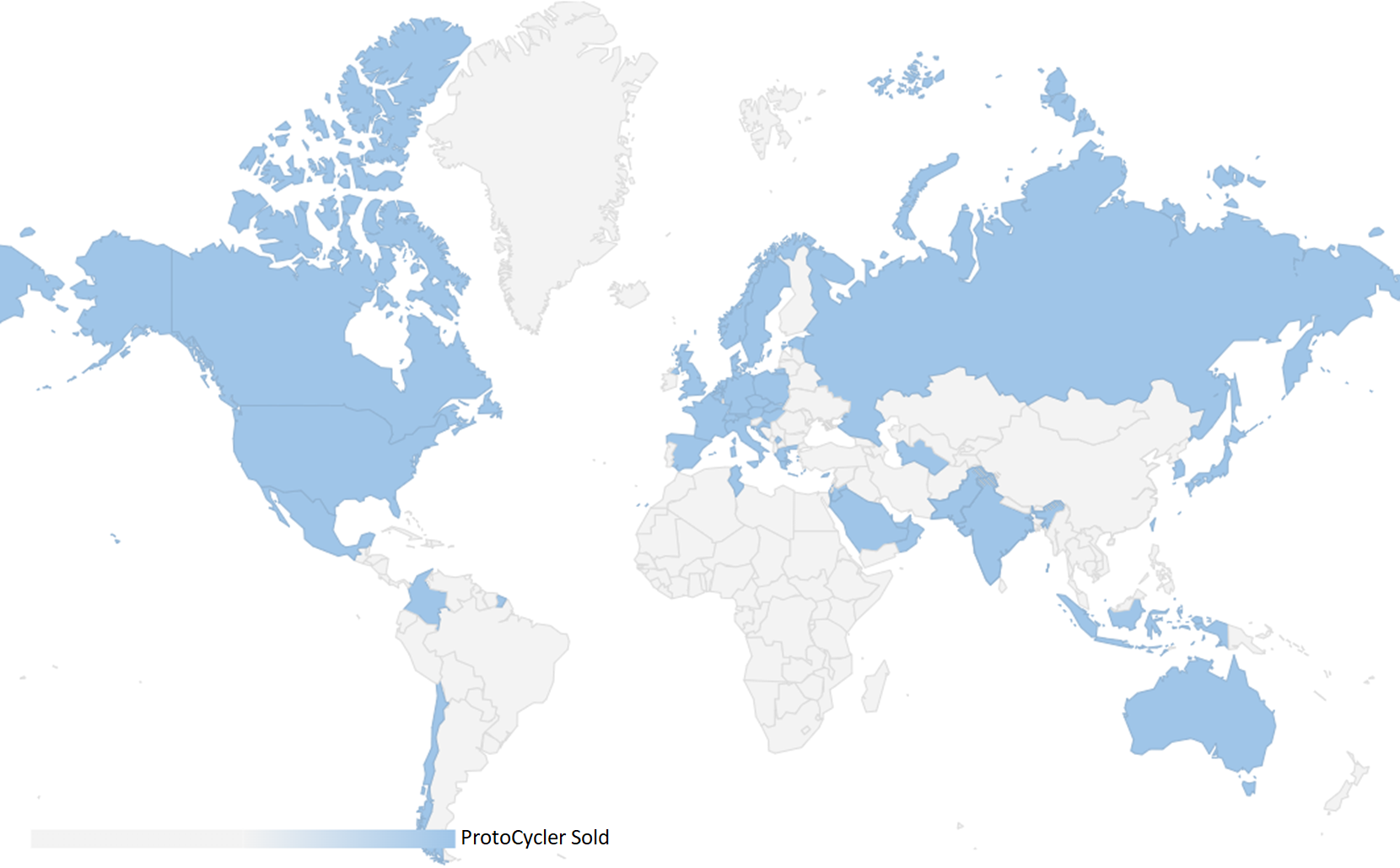

Gain a Global Edge

ProtoCycler is used by hundreds of businesses around the world to gain an edge on the competition. Don't be left behind - contact our sales team today to see how ProtoCycler can help your business thrive.