Researchers and Educators at some of the world’s largest institutions rely on ProtoCycler for its unparalleled quality, safety, and ease of use.

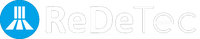

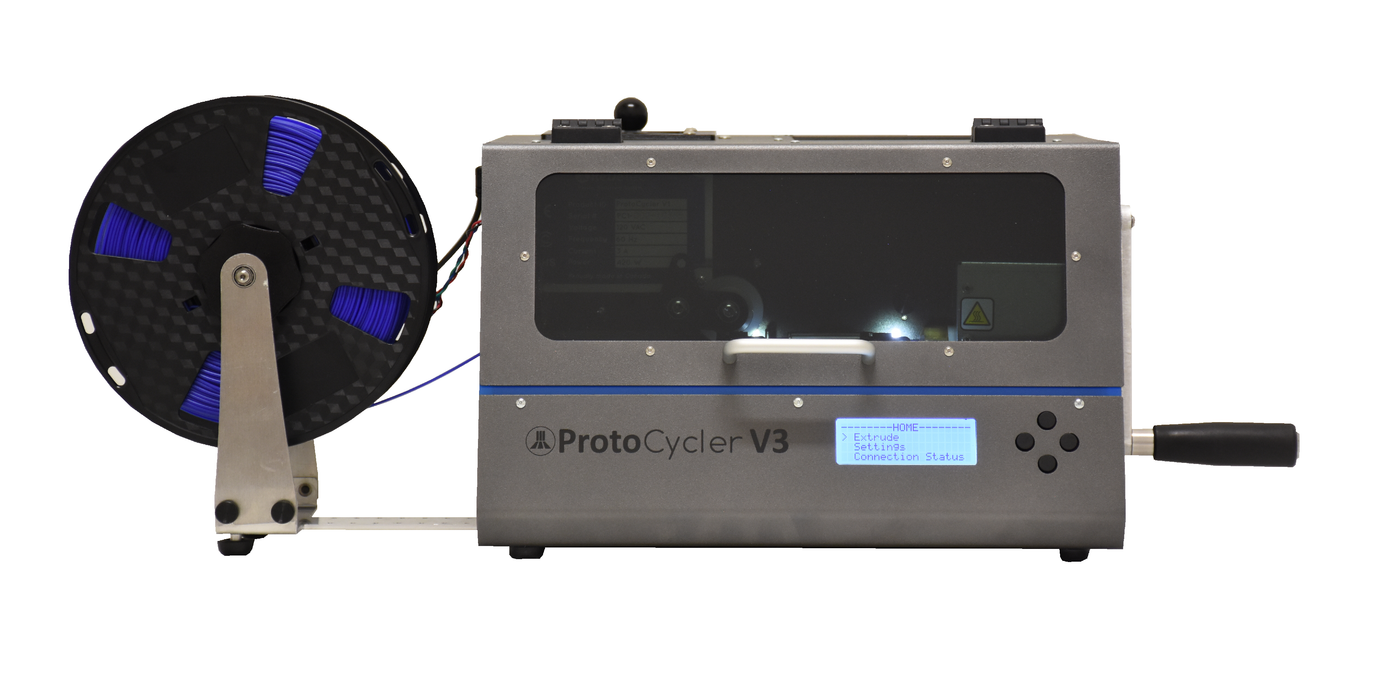

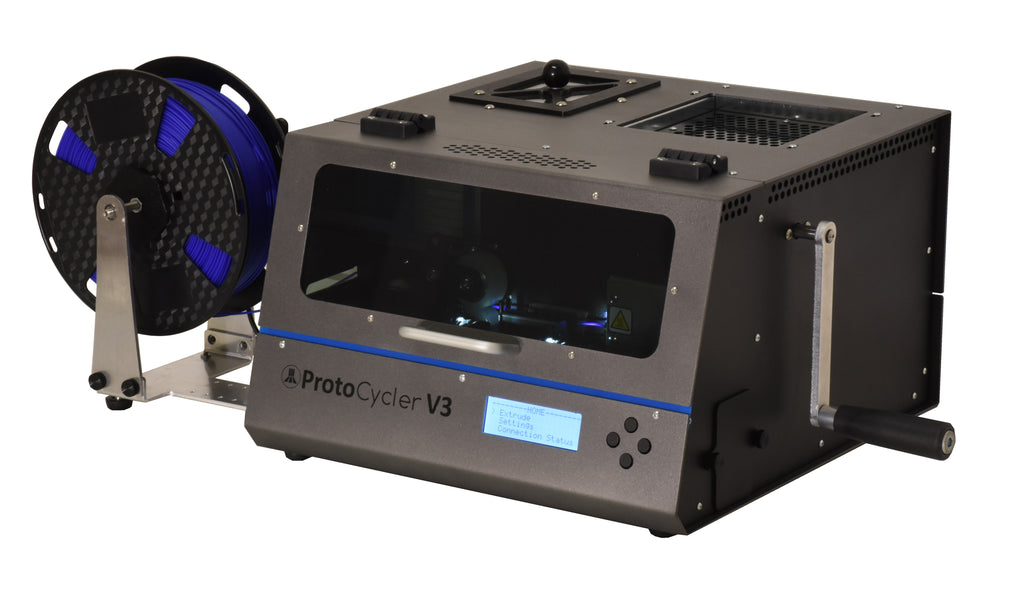

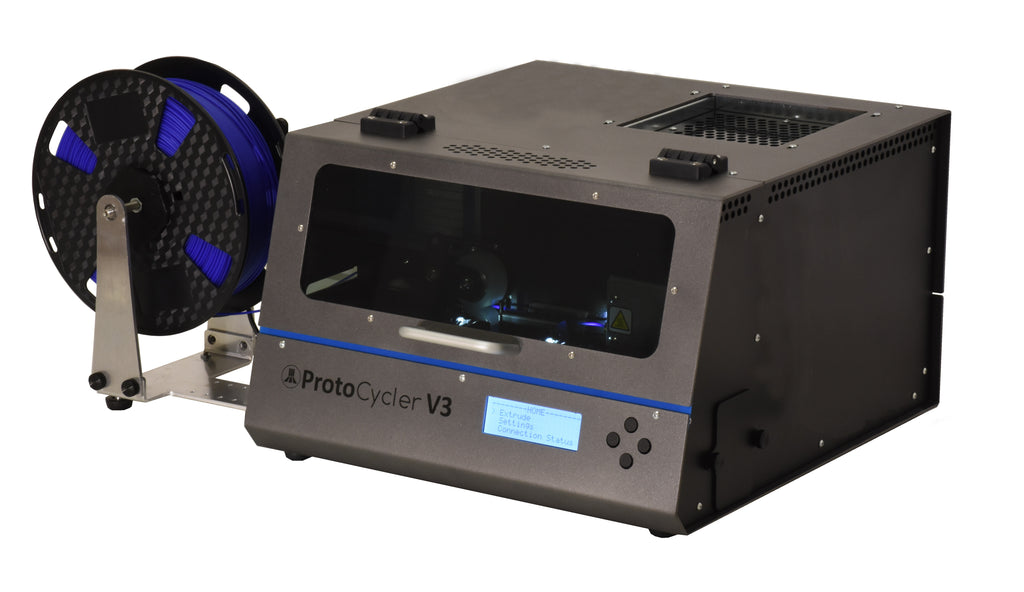

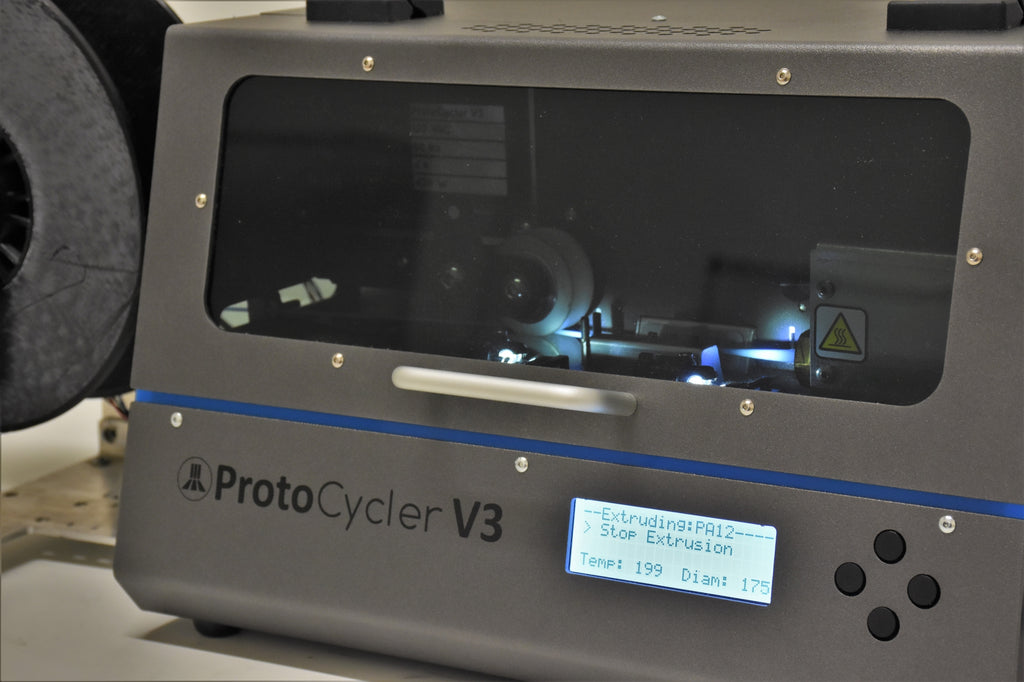

ProtoCycler V3: The Most Advanced Filament Extrusion System for Education and R&D

Custom 3D Printer Filament, On Demand

Create custom 3D printing filament on demand with ProtoCycler V3.

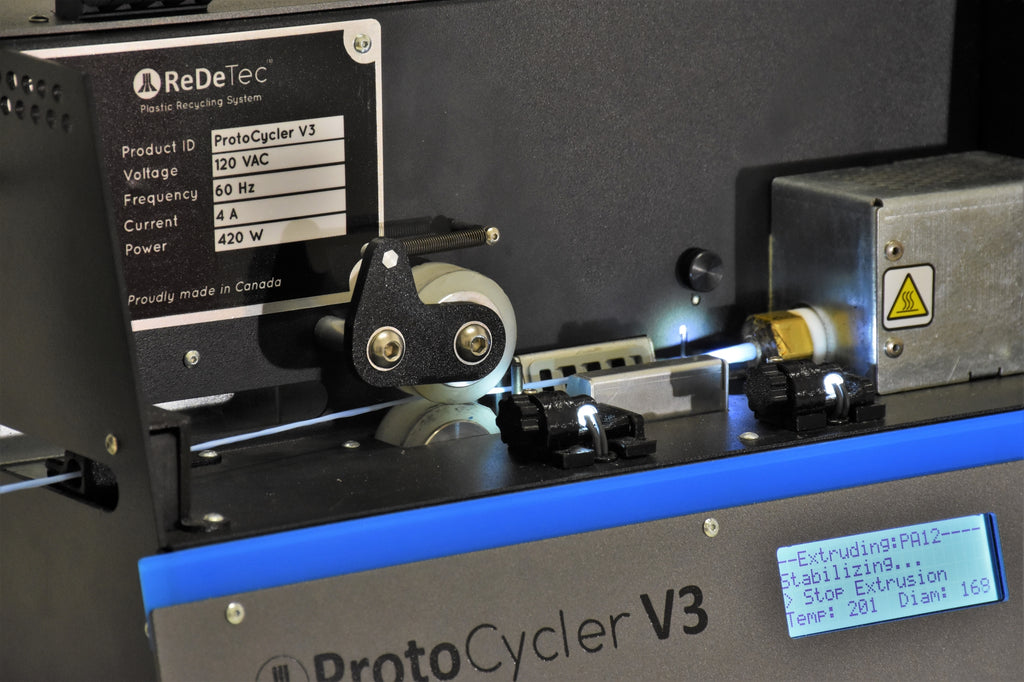

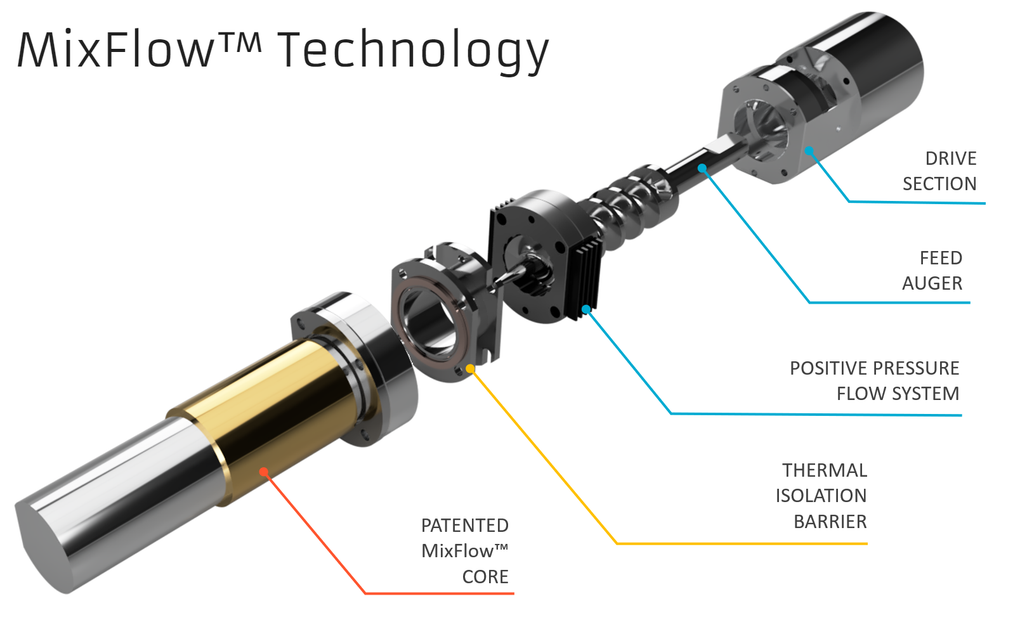

Patented MixFlow technology outperforms the competition - at any price point - and results in the highest quality filament possible.

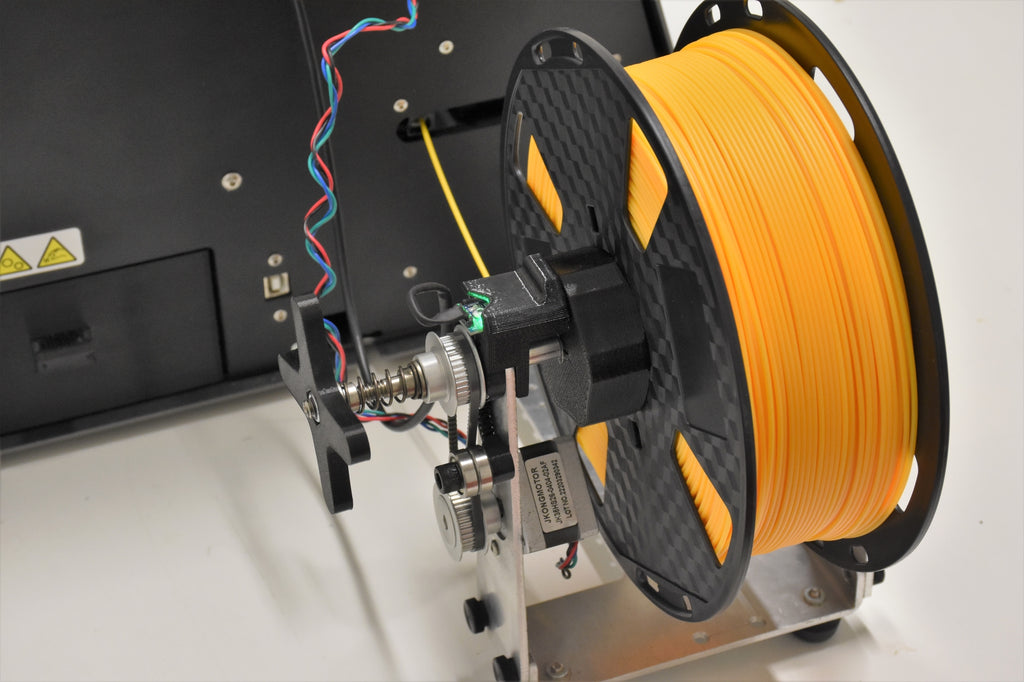

Intelligent control systems handle every aspect of extrusion - automatically ensuring your 3D printer filament is always in spec.

Advanced software, 3rd party safety certification, and available grinder are all exclusive to ProtoCycler V3 - no other system offers this much technology, or this level of performance.

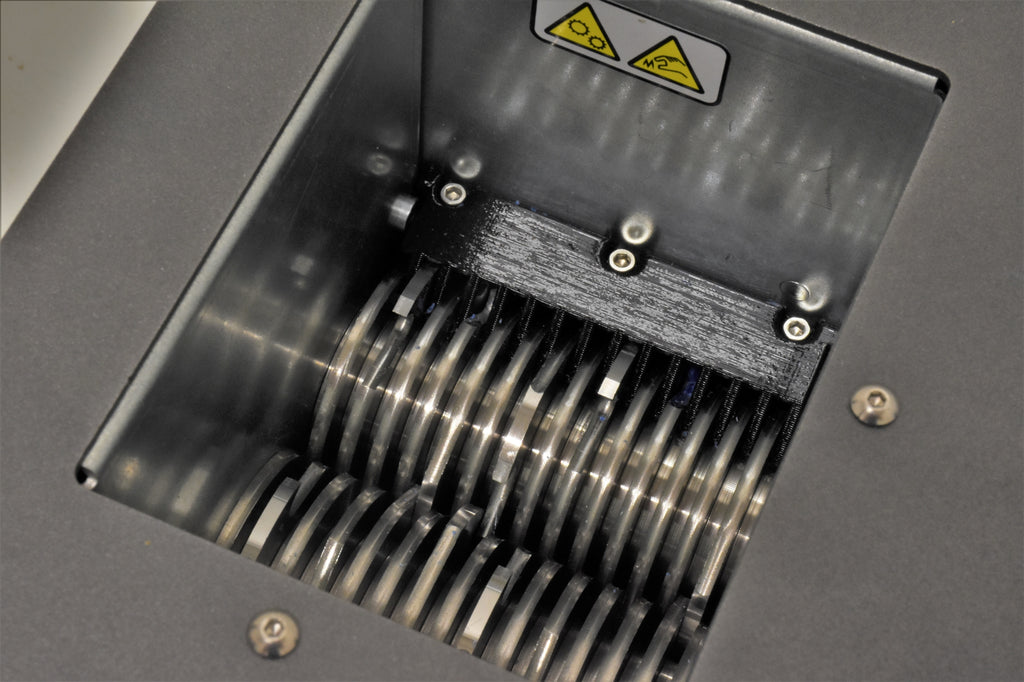

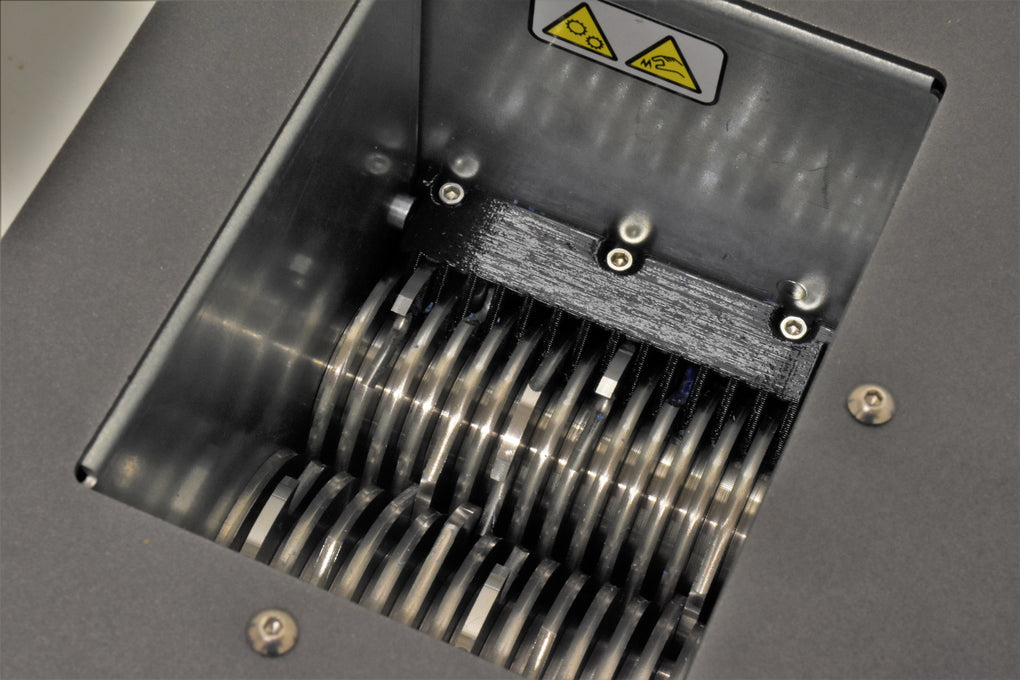

Recycle your 3D Printing Waste

Save your wallet - and the planet. Reduce 3D printing filament costs by 80% and recycle all your waste in the process.

ProtoCycler V3 is the only extruder on the market available with an optional grinder that can shred 3D printing waste - such as rafting or support material - into granules that can be used to make new filament.

Certified safe for the lab or classroom, ProtoCycler V3 eliminates your 3D printing waste, and provides sustainable 3D printing filament.

Unleash your 3D Printing Creativity

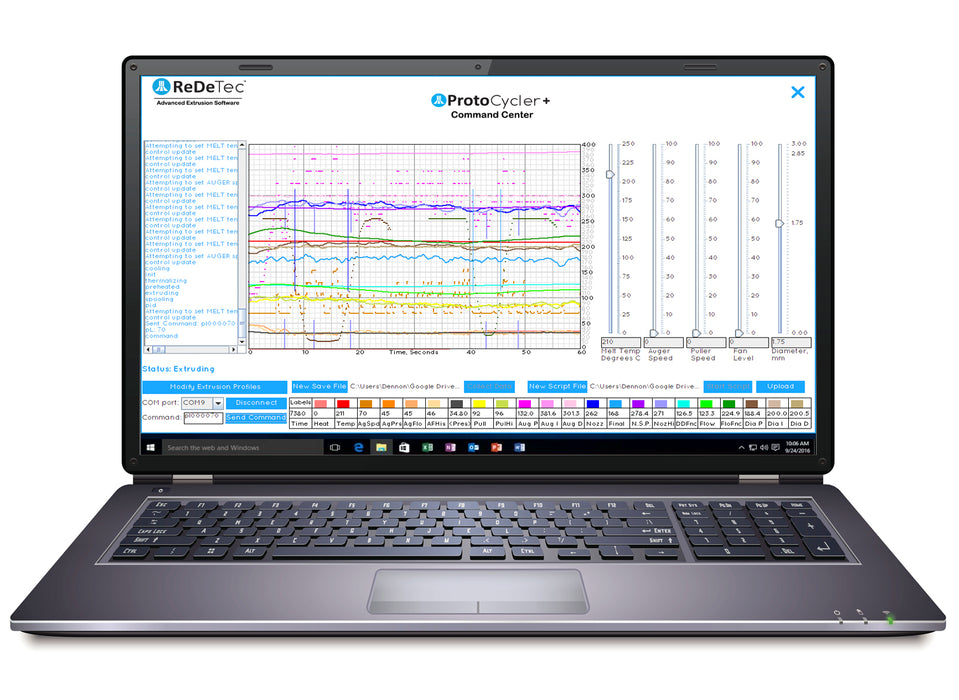

ProtoCycler V3 comes with our Command Center software that tracks 20+ parameters related to filament extrusion, allowing you to experiment and create new materials for 3D printing or otherwise. Command Center is the most comprehensive filament extrusion software available.

Powered by artificial intelligence, it is able to learn and optimize new plastics, and can be safely run on autopilot. Frequent firmware updates ensure your system is always top of class, and are free for life.

Trusted Around the World

Cutting Edge Filament Extrusion

MixFlow™ Filament Extrusion uses 3x less energy than competitors, while offering superior throughput and performance. Proven to create higher quality filament, at lower cost, than any other system.

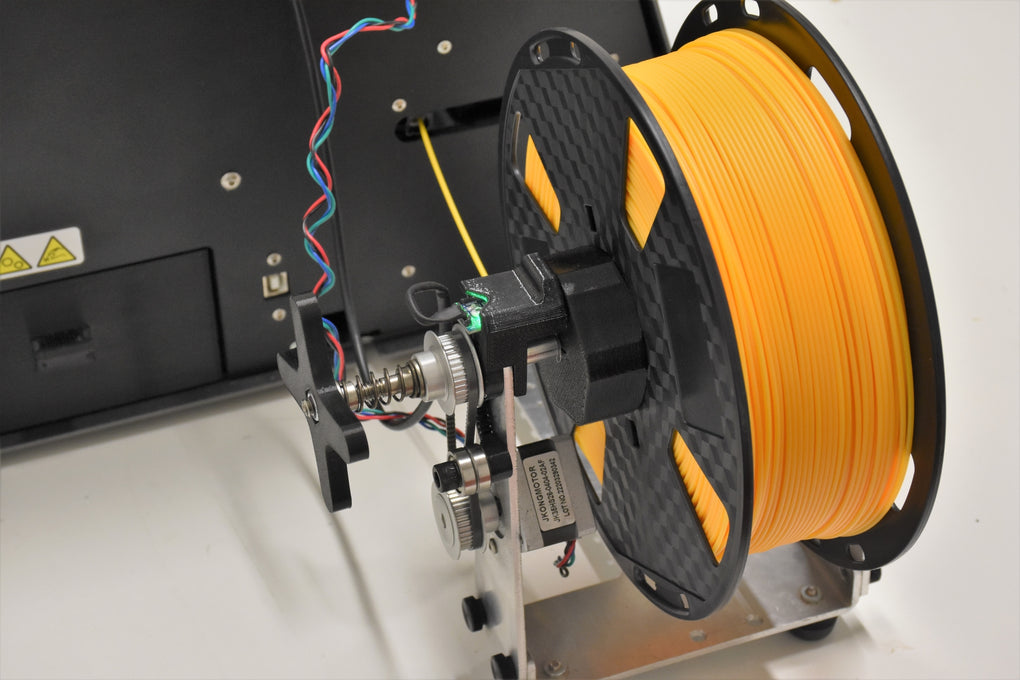

A Fully Equipped Filament Factory

ProtoCycler V3 comes completely ready to go - with an integrated extruder, digital control system, filament cooling system, and intelligent spooling system.

Don't settle for others that make you buy everything separately - Purchase ProtoCycler V3 today.

Independently Certified. Globally Compliant.

No other filament maker/extruder is fully certified to global standards. From the classroom to the lab, we are certified to UL standards for thermal, electrical, and mechanical safety and are FCC/CE compliant. We really care about the environment, so we manufacture in full compliance with RoHS directives.

ProtoCycler V3 is the safest 3D printer filament maker/extruder on the market.