ReDeTec Verifies MixFlow™ Extrusion Technology in Plastic Recycling Study

Thermoplastics are created from raw materials every day, and often follow a lifecycle that culminates in the pollution of our planet. Recycling this plastic is crucial to the reduction of environmental waste - but traditional recycling techniques degrade the plastic, reducing its usefulness. How can plastic be effectively used again, without reducing the inherent usefulness of the material?

ReDeTec’s patented MixFlow™ extrusion technology is designed to maintain the desired mechanical properties of the plastic while recycling it into raw material once again - avoiding the degradation inherent to other recycling methods. By reducing thermal degradation and eliminating viscous shear within the molten plastic, ReDeTec’s MixFlow extruders are able to maintain the mechanical properties of four commonly used 3D printer plastics: Polylactic acid (PLA), Acrylonitrile Butadiene Styrene (ABS), High Impact Polystyrene (HIPS), and Polypropylene (PP).

ReDeTec’s ProtoCycler V3 filament extruder equipped with MixFlow™ extrusion technology.

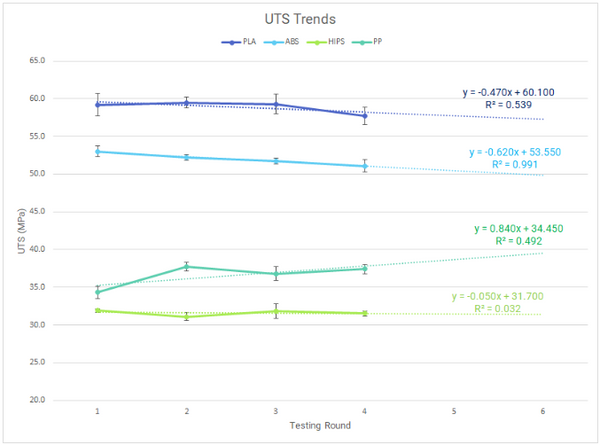

A study conducted by ReDeTec R&D engineers showed that after three recycling cycles, the ultimate tensile strength (UTS) and elastic modulus of PLA, ABS, HIPS, and PP samples remain relatively unchanged when recycled using the MixFlow™ technology. This is a highly promising result for the future of MixFlow™ technology, indicating its potential to play a major role in the future of sustainable plastics use.

Dogbone samples of plastic are put in a tensile testing machine to determine their mechanical properties.

During this study, plastic samples were 3D printed, mechanically tested, and then recycled back into filament using the ProtoCycler. These samples were then used and tested again in order to determine how the mechanical properties of the plastics changed throughout the recycling process. The samples were recycled a total of three times. With the exception of polypropylene’s elastic modulus, the average UTS and elastic modulus for each plastic remained consistent across all rounds of testing - under 1% on average per round, compared to industry standards of 10% or more with competing methods of recycling.

UTS Trends showed deviations less than 1% per recycling round for PLA, ABS, and HIPS - PP showed <2.5% variation.

With ReDeTec’s MixFlow™ extrusion technology, the future of plastic has the potential to become more sustainable. By promoting both plastics recycling and waste reduction, ReDeTec is aiming to provide ecological and economical advantages over current industry standards, with MixFlow™.